Through 3D Nanoprinting nano3DSense Seamlessly Adapts to Your Measuring Environment!

MEMS (MicroElectroMechanical Systems) transform mechanical into electrical energy  and vice-versa. They normally consist of a small bendable mechanical substrate, such as a pressure diaphragm or force substrate (e.g. cantilever) and a transducer for specific measurements. The challenges on the measuring technology increase significantly with progressing miniaturization and the conditions on the substrate material. If such devices are miniaturized to the nanometer level of several hundred nanometers (nm) only, they are referred to as extremely compact NEMS (NanoElectroMechanical Systems).

and vice-versa. They normally consist of a small bendable mechanical substrate, such as a pressure diaphragm or force substrate (e.g. cantilever) and a transducer for specific measurements. The challenges on the measuring technology increase significantly with progressing miniaturization and the conditions on the substrate material. If such devices are miniaturized to the nanometer level of several hundred nanometers (nm) only, they are referred to as extremely compact NEMS (NanoElectroMechanical Systems).

The Limits of Conventional Metrology in Industry and Research

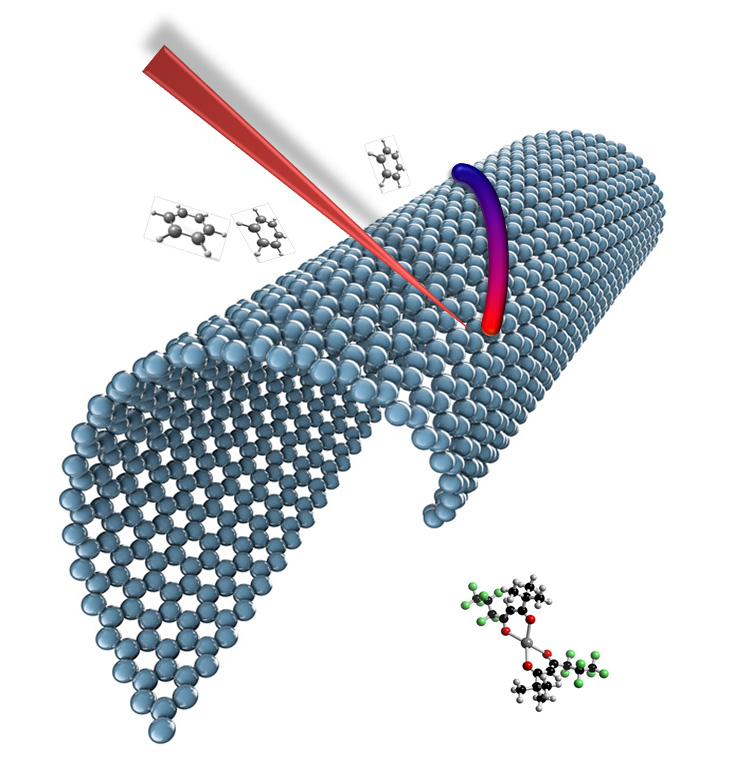

Conventional devices for force, pressure or strain measurements, such as lasers, piezo resistors, or capacity sensors, quickly reach their limits in the case of highly miniaturized MEMS/NEMS applications, often already at dimensions below 20 microns (µm) (1 µm = 1000 nanometers).

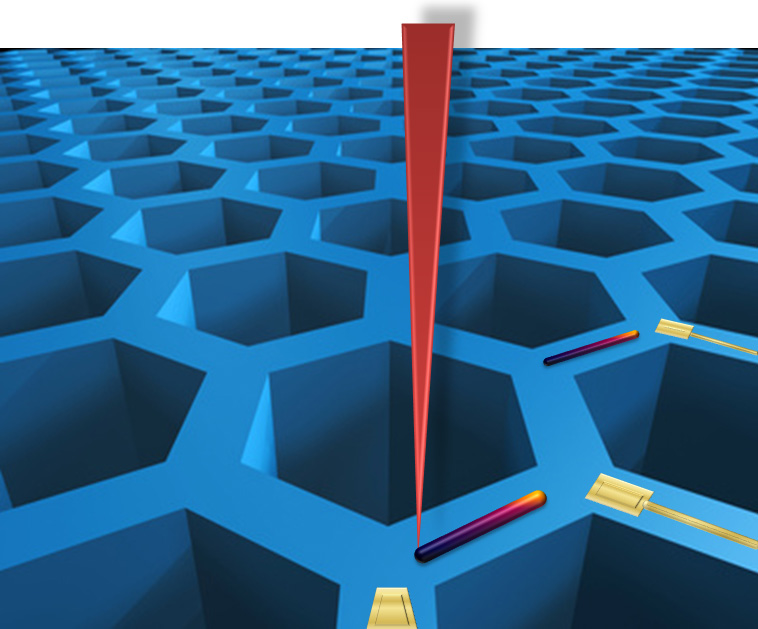

In case of methods that use a focused laser spot e.g., the diffraction limit of the laser, which cannot become smaller than 1.4 µm (HWFM, “Half Width at the Full Maximum”), already represents a natural and ultimate barrier for further miniaturization of optical probes.

The situation is similar for other force sensors, such as piezo resistors. As they require sophisticated cleanroom and doping processes, the miniaturization potential is often already exhausted at dimensions of 20–50 µm. Furthermore, these traditional sensor approaches strictly require silicon as a base material, which is not desirable in certain cases. In case of other materials, such as steel or polymers, force and pressure can only be measured if complicated detours e.g. gluing and joining techniques or oil filled chambers are employed.

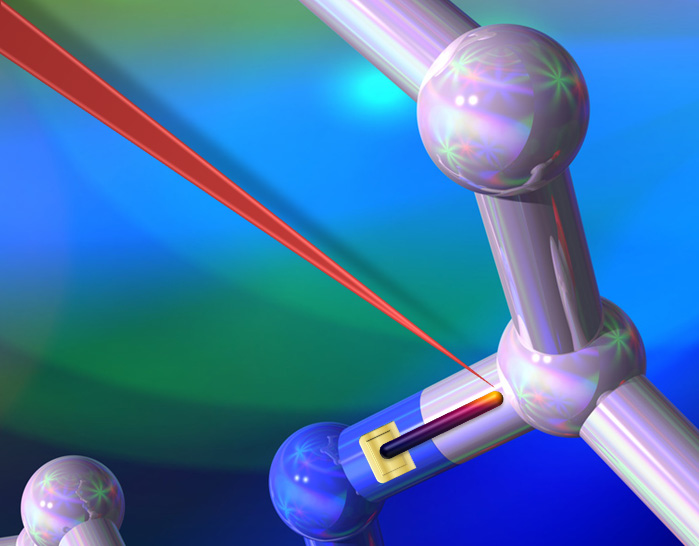

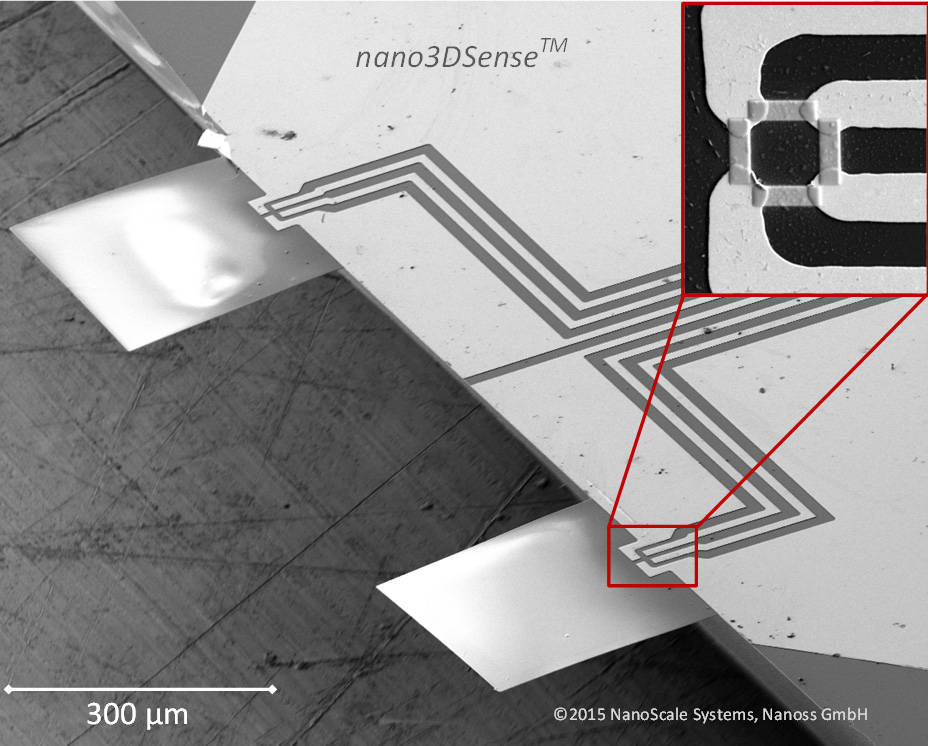

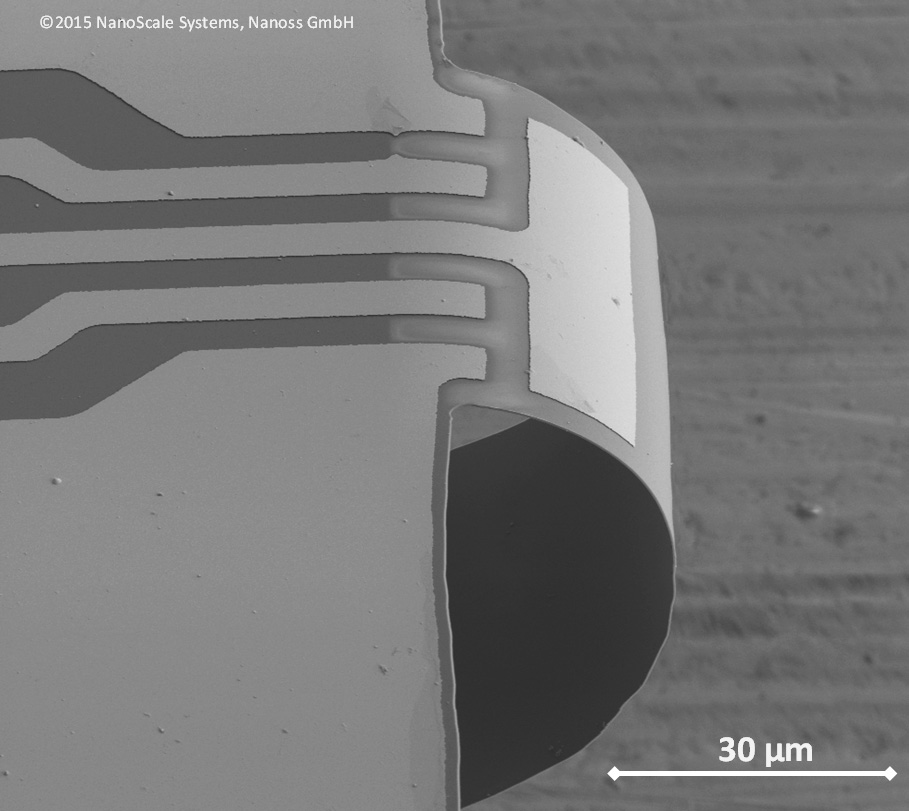

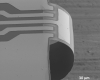

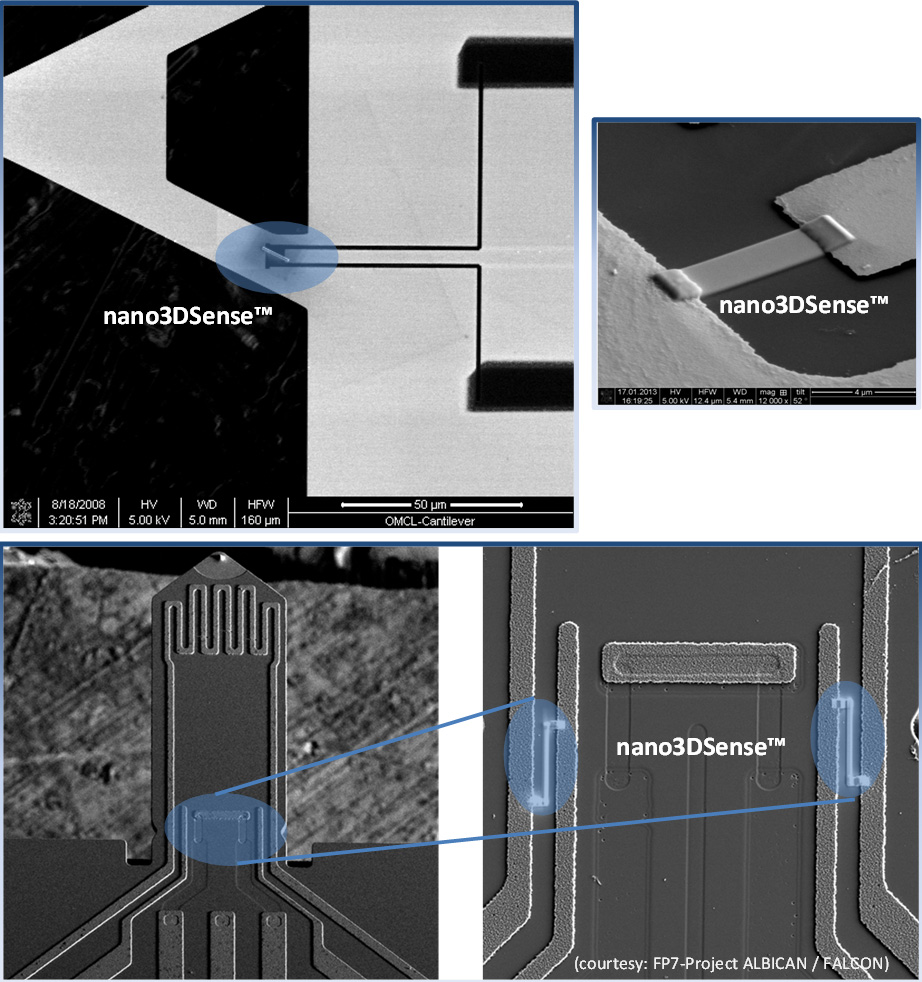

These cumbersome and error-prone processing steps in mainstream cleanroom technology can be greatly eliminated with the new patented nano3DSenseTM technology: Thanks to the innovative 3D nanoprinting, high-performance sensors can be directly applied with nanometer precision on all materials and are immediately ready for use in your MEMS/NEMS application.

Printable Sensors for MEMS/NEMS on the True Nanoscale

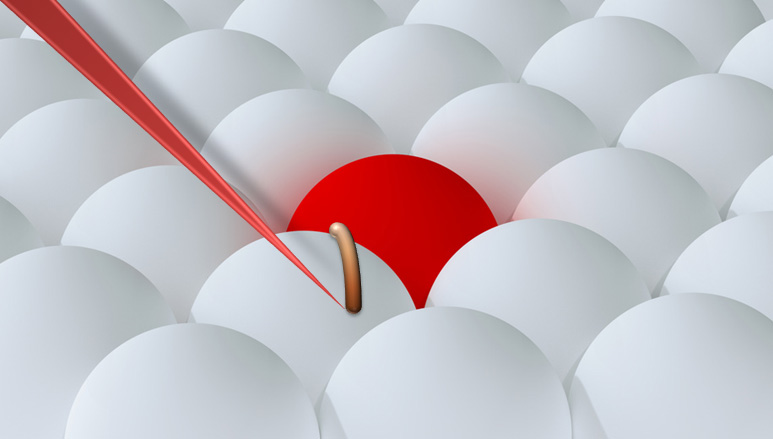

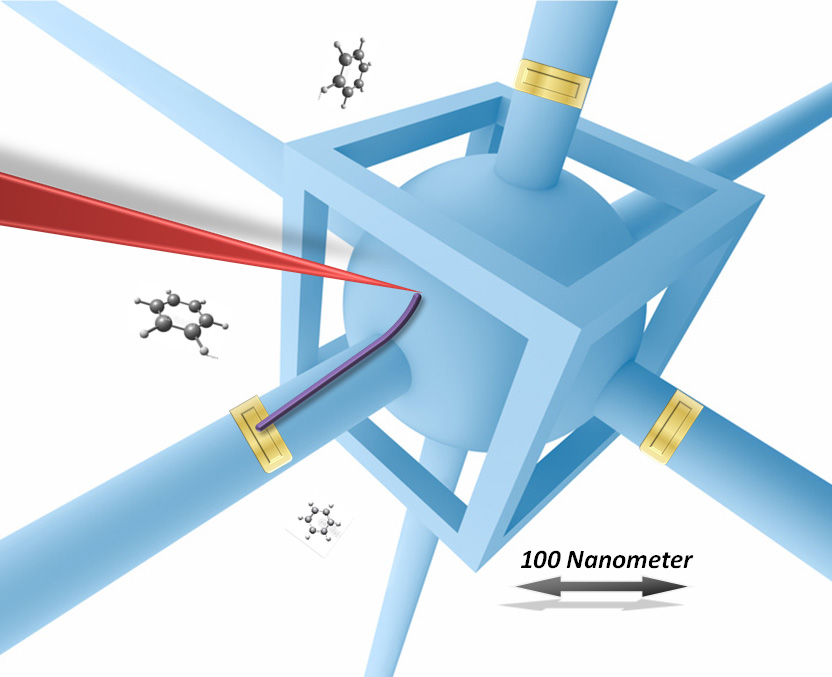

With nano3DSenseTM, sensors are printed for the first time using 3D printing with true nanometer precision onto desired locations, where they are immediately available for powerful measuring tasks. And this independently from material substrates or the nature of the surface. All materials made of e.g. silicon, oxides, plastic, polymers, steel, ceramics, and more are suitable.

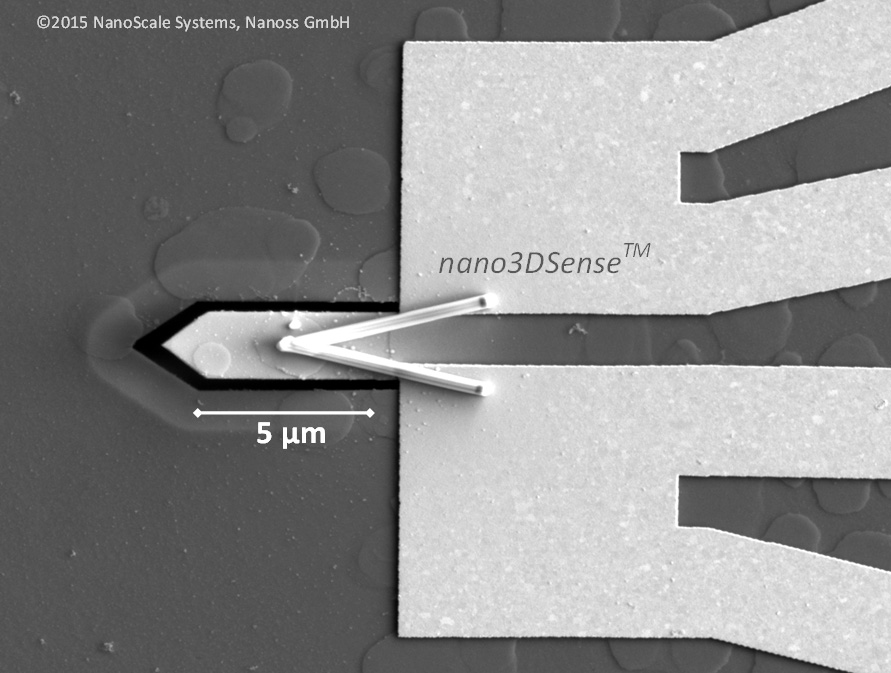

nano3DSenseTM adapts seamlessly and in the best possible way to every MEMS/NEMS environment and offers a positioning accuracy on the substrate of less than 5 nanometers for sensor dimensions down to 10 nanometers (if needed). This is a world record! The sensor is accurately applied exactly at the point, where forces, pressure and other measuring variables actually occur or must be measured very precisely. Unlike in the case of e.g. piezo resistors or strain gauges, no interfering intermediate layers or complex bonding or joining technologies are required anymore.

3D printing on the nanoscale also allows adapting to the geometrical boundary conditions of the MEMS/NEMS component quickly. The sensor is simply printed three-dimensionally (3D) onto the MEMS/NEMS surface (see example graphics above and below) and are there immediately available for your measuring tasks – bypassing sophisticated cleanroom and mask processes.

Whether for highly custimzed production, rapid prototyping or R&D during the new development of demanding MEMS/NEMS applications, or for fast testing of a new sensor design: 3D nano printing will always provide you with an advantage of time, costs and flexibility when implementing your ideas.

Unparalleled Advantage in Miniaturization and Adaptivity

nano3DSenseTM is a cross-technology platform for industry and R&D, and covers a variety of dedicated tasks with sensor background. If you have highest demands on miniaturization and adaptivity to the measuring environment or the material, newly exploit the entire spectrum of force and pressure sensors for your MEMS/NEMS applications, such as

- Force and pressure sensors for medical devices, such as catheters, implants, and prostheses

- Analytics: detection of antibodies, proteins, DNA, viruses/bacteria, and cell analyses, as well as force spectroscopy

- Medical diagnostics: early diagnosis of diseases, such as diabetes and tumors

- Gas measuring technology, e.g. for hazardous gases and explosives in personal protection

- Compact and fast atomic force microscopy (AFM) without laser optical devices

- Pressure sensors for vacuum pressure and laboratory technology (gas flow/mixing systems/leak detectors, etc.)

- Force, pressure, acceleration, torque, and vibration sensors in the robotics, automotive, entertainment electronics, and aerospace industry as well as many other micromechanical tasks

We closely collaborate with developers and manufacturers of MEMS/NEMS and general sensors to meet these new challenges.

Please contact us: We are looking forward to inform you about all advantages of the new nano3DSense technology and the application possibilities in your specific area.

You can also request a demo and thoroughly test nano3DSense.

Read More:

What We Can Do for You

Tailored Customer Solutions in Medicine

Medical Sensors for Implants and Catheters

Point of Care (POC) Diagnostics

Sensors for MEMS/NEMS

⇒ Ultra-Small Force Sensors

Rapid Prototyping