Revolutionary 3D Nanoprinting for ultra-precision and adaptive sensor manufacturing

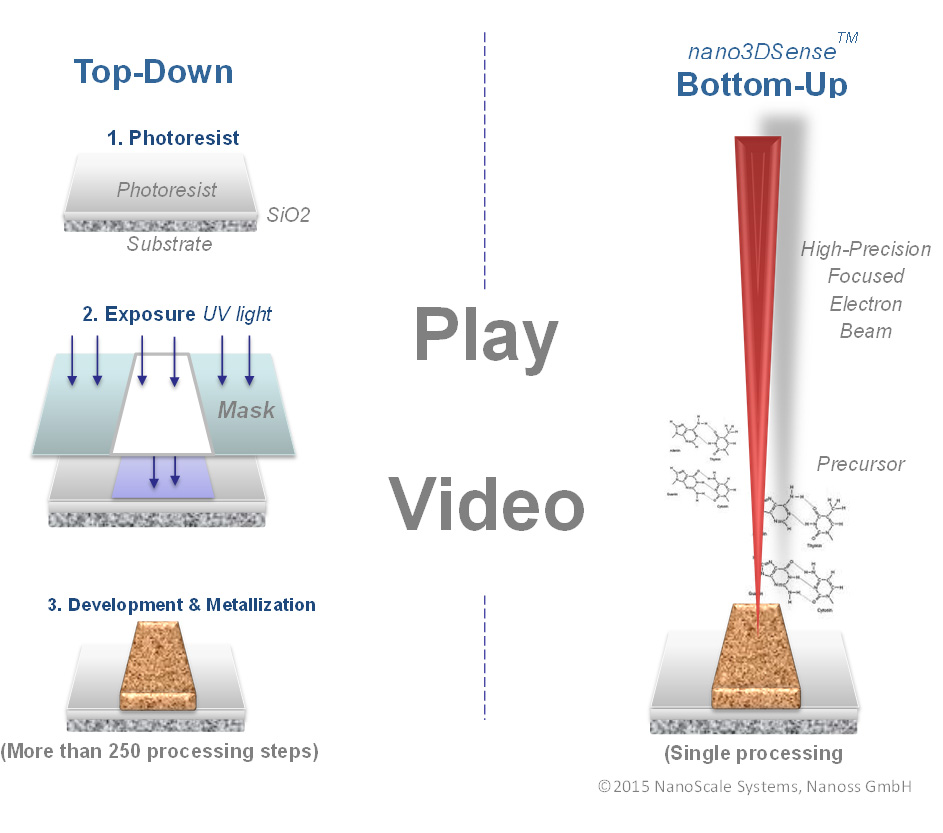

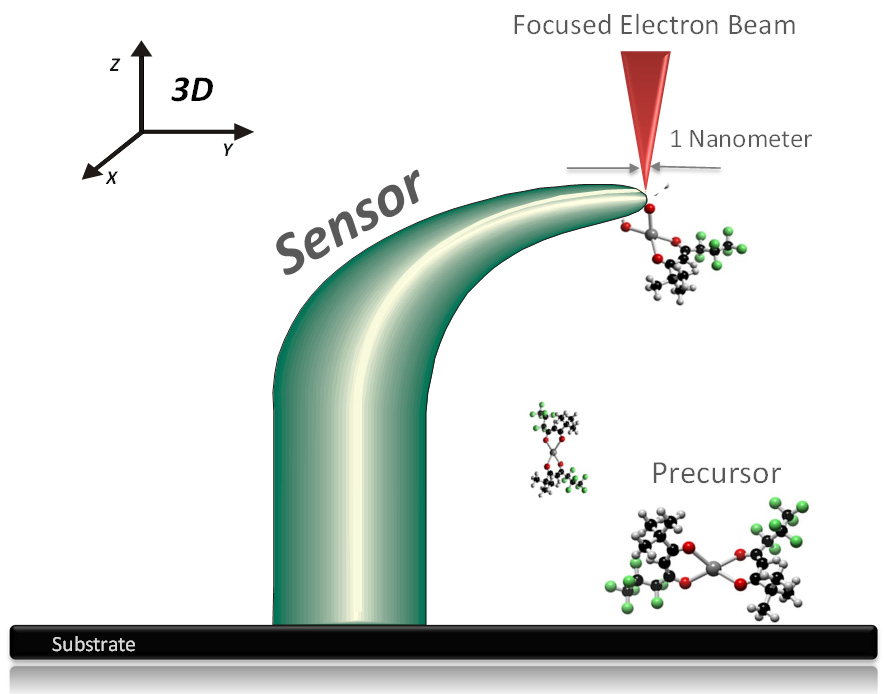

nano3DSense is a new generative (“bottom-up”) manufacturing technology, which enables seamless 3D printing on the true nanoscale of microelectronic components, such as force, pressure and strain sensors, onto customer-specific material substrates. In contrast to the classical semiconductor approaches used in cleanrooms (“top-down”), with maskless nano3DSense no error-prone multi-step lithography technologies or costly cleanroom processes are needed anymore.

For Series Production or Rapid Prototyping: More than 250 Processing Steps in Cleanroom Technology can be saved

Unlike traditional (top-down) methods in cleanroom environment, our patented nano3DSense manufacturing process completely avoids photo mask lithography and other silicon processing technologies. This way, we can not only eliminate more than 250 complex multi-step processes in the manufacturing of sensors and simplify the production effort. Using unique rapid prototyping capabilities, provided by nano3DSense, the complete cycle in the development of new product generations can be incredibly customized and accelerated as well. This guarantees tailored solutions and maximum profit for your application even in the case of small series production.

Read more:

nano3DSense at a glance

Top-Down vs. Bottom-Up

> Nano 3D-Printer

How the nano3DSense sensor works

Features

FAQ: nano3DSense