Bypassing Historical Hurdles

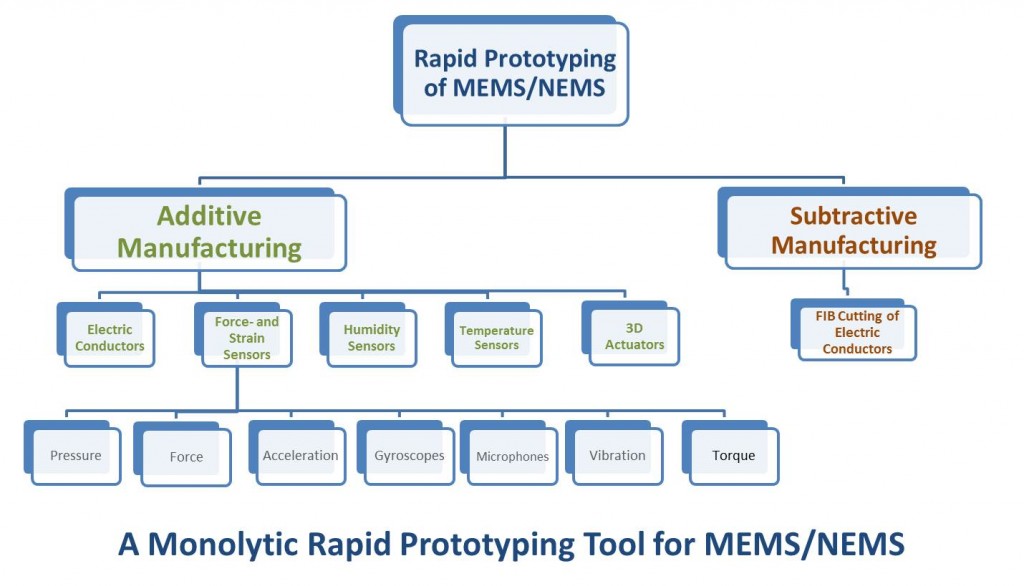

nano3DSense offers unique rapid prototyping capabilities for electronic circuits and all kinds of MEMS/NEMS applications. In particular, if a new sensor idea must be quickly implemented, conventional cleanroom technologies, such as mask lithography, have significant disadvantages. E.g. due to long delays of several weeks and significant additional costs: Every time, the sensor design is changed – even slightly, for optimization purposes, new masks must be produced and the whole time consuming cycle of “top down” steps, such as UV exposure and lift-off, must be entered again. Several such iterations are often required up to series production maturity of a new product idea.

Using nano3DSense as a powerful rapid prototyping tool, you print your sensors, electronic circuits or mechanical actuators simply and ready for operating onto your product or the desired substrate bypassing these annoying intermediate steps.

Reaching the Goal in Only Four Steps

In combination with focused ion beam (FIB) cutting, you are even completely independent from the final circuit layout. The electronic wiring of the sensors on the integrated chip can also “on the fly” modified to your needs using a focused ion beam so that you do not have to decide on a final design upfront.

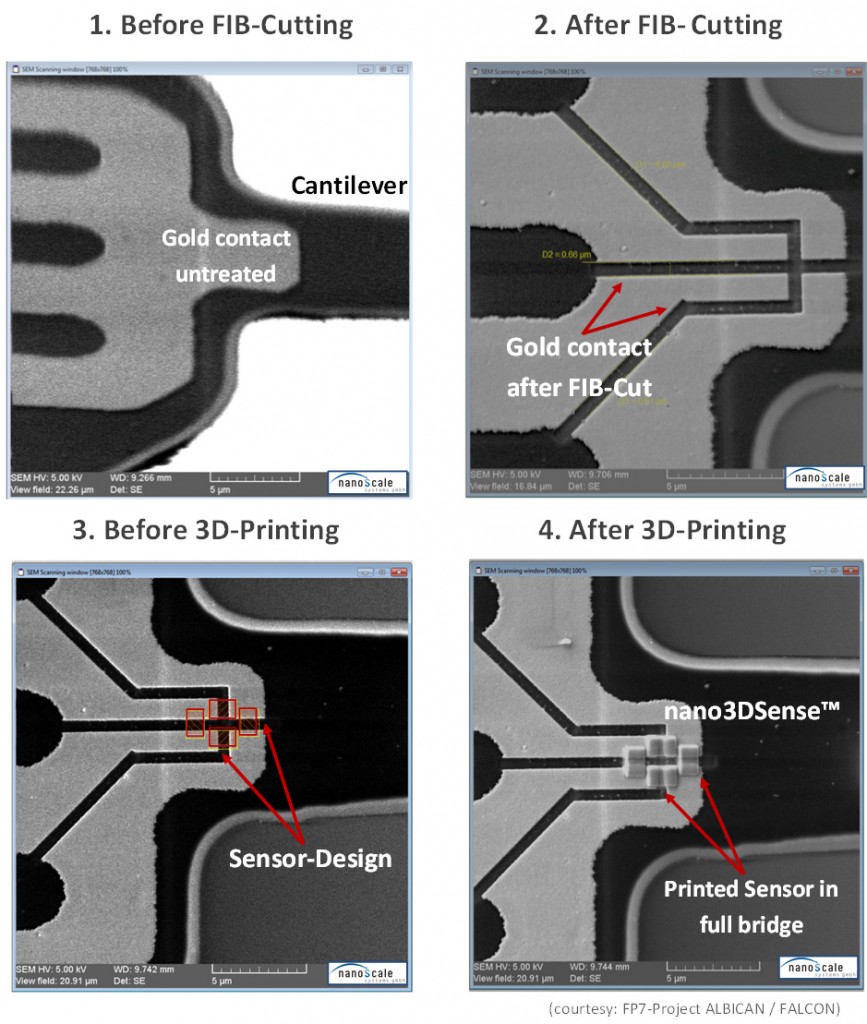

The figure illustrates the rapid prototyping process using nano3DSense and FIB cutting in four steps:

- The figure shows the example of a micro chip with pre-structured gold contacts.

- Using FIB cutting, a dedicated layout should be provided for the conductors in the center of the gold contacts. The gold material is removed within seconds with nanometer precision using the focused ion beam, until the desired layout is exposed.

- In the next step, the sensor design is defined in the center of the exposed conductor using a CAD program.

- nano3DSense now assumes control by printing a force-sensing nano material directly onto the desired location, within a minute.

Tailor-made Sensor Design

Nanoss GmbH offers comprehensive and sophisticated services for your R&D projects to support you in the fast and cost-effective implementation of your ideas. Here you benefit from the many new advantages of the new sensor technology, such as nanometer precision, independence from sensor substrate and/or substrate material, and the unrestricted 3D sensor adaptation to every substrate geometry

No matter, what you decide: whether you prefer the realization of series production later based on nano3DSense via a fully automatic batch process, or using a different sensor technology, such as piezo resistors:

With nano3DSense and the unique rapid prototyping technology, we can significantly shorten the path from planning to product maturity.

Contact us: we are looking forward to address your ideas individually and to specifically advice you on the application possibilities of the new rapid prototyping technology.

You can also request a demo and thoroughly test nano3DSense.

Read More:

What We Can Do for You

Tailored Customer Solutions in Medicine

Medical Sensors for Implants and Catheters

Point of Care (POC) Diagnostics

Sensors for MEMS/NEMS

Ultra-Small Force Sensors

Rapid Prototyping