Precision on the Nanometer Scale: Unbeatably Small and Flexible in Medical Technology

Medical technology today cannot be imaged anymore without the use of force and pressure sensors. Miniaturization and biocompatible materials are particularly important if minimum invasive intervention and maximum tolerance to the human body is of highest priority, e.g. in the case of catheters and long-term implants. To enable the best-possible therapy for the patient, highest requirements are placed on gentle as well as tissue-compatible medical equipment. The requirements on reliability, precision, durability and a balanced price-performance ratio have continuously increased during recent years, and will further increase.

Pressure Diaphragm for Your Medical Applications

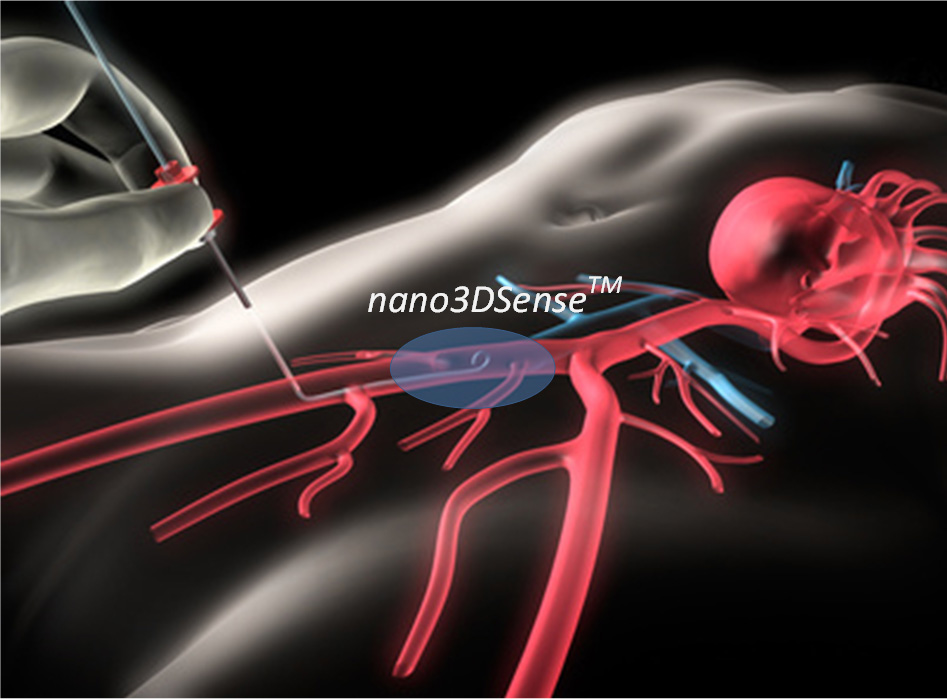

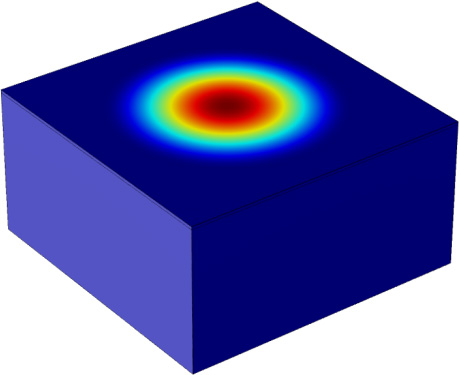

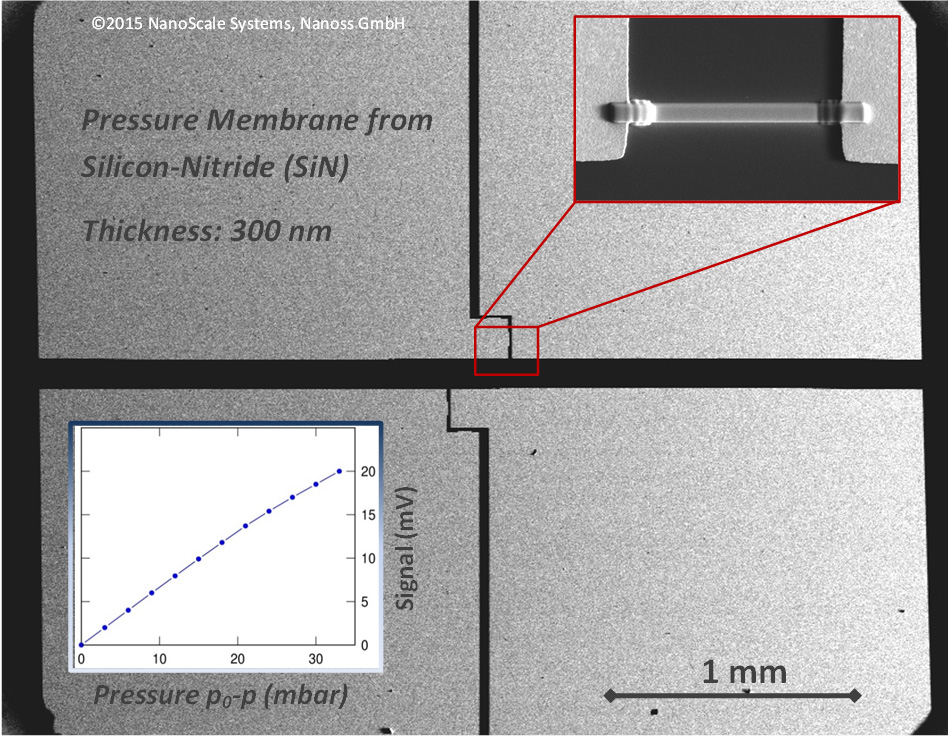

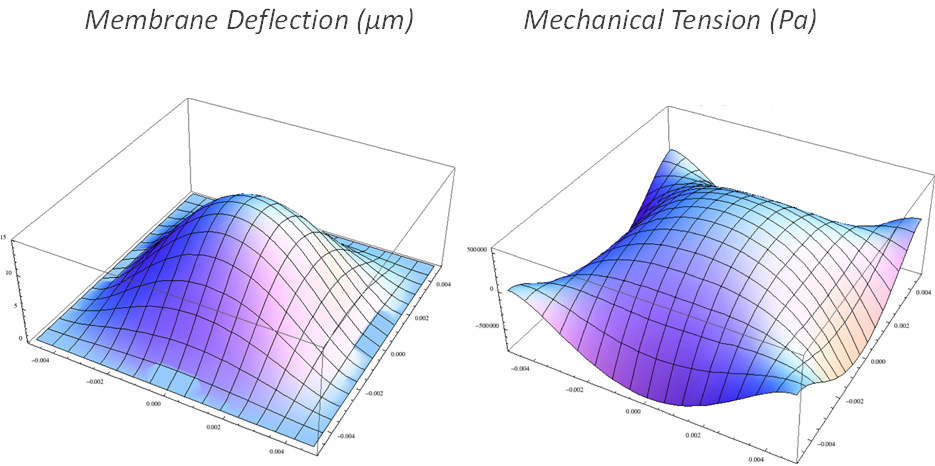

Every pressure measurement in the body is based on the diaphragm (or membrane), e.g. for short or long-term intravascular, intracardiac or neurovascular blood pressure measurements. Its minimum size and material consistency mainly determine the actual benefit and application possibilities, e.g. as diagnostic implants or catheters in the treatment of hypertension, heart failure and minimally invasive surgery. Pressure diaphragms also play an improtant role in the monitoring of many other body organs, such as implants for intraocular pressure (IOP) for the diagnosis of glaucoma, intracranial pressure, bladder pressure, stomach pressure and even in the case of glucose monitoring (CGM).

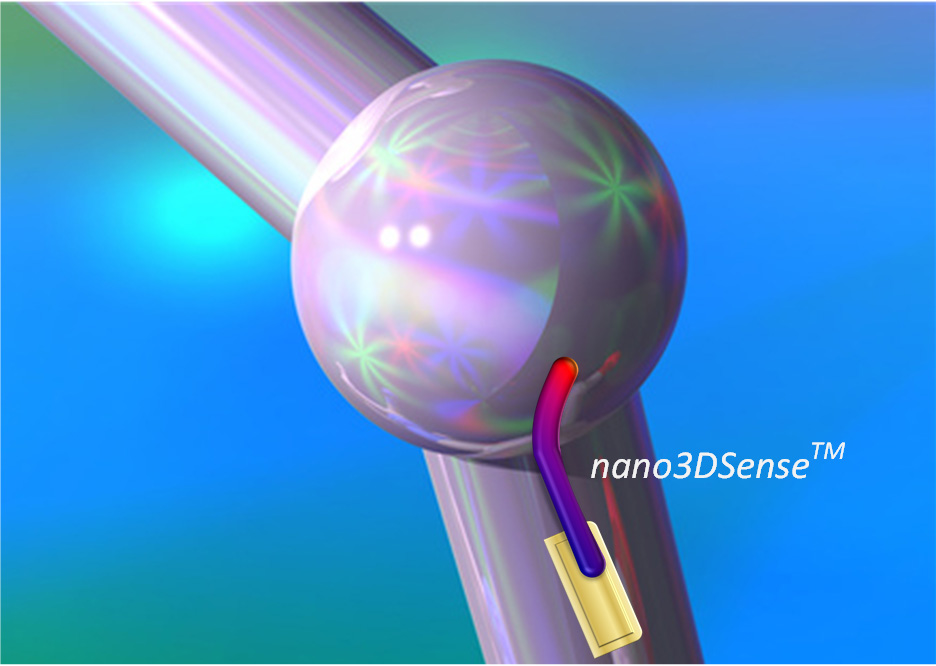

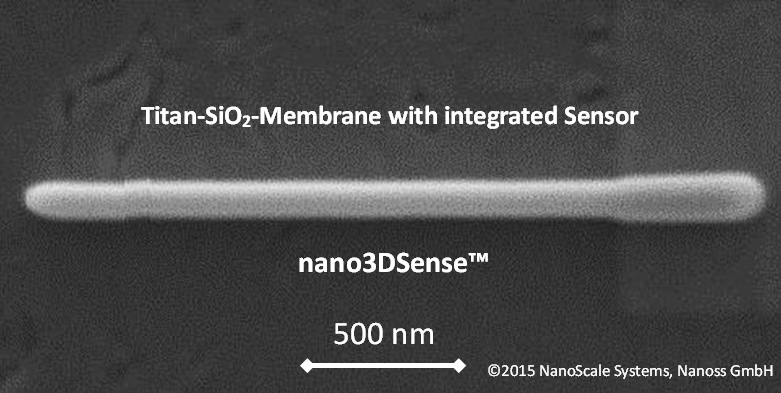

Nanoss GmbH has invented the groundbreaking nano3DSense-technology platform which – compared to traditional capacitive, piezoresistive or optical fiber (Fabry-Perot) methods – provides significant benefits in the sensor design: A higher form factor of at least 10x in minimally invasivity can be achieved, when compared with conventional pressure or force sensors. The new approach with patented 3D Nanoprinting also allows to print sensors directly on your medical device (e.g. catheter or implant) thus simplifies your sensor design radically. As a result biocompatibility and minimally invasiveness can be chosen with nearly unlimited flexibility and the effort for your measurement setup (sensor and readout) can be reduced to the absolute minimum requirements.

Outperform your expectations: Benefits for Your Applications in Industry and Research (R&D)

We closely collaborate with medical equipment developers and manufacturers to meet todays and tomorrows challenges with highest possible priority. The ultra-compact sensors of Nanoss GmbH set new standards with respect to minimally invasiveness, biocompatibility, flexibility and greatest possible care for force and pressure measurement catheters and implants in medical applications:

- Enabling technology for challenging tasks in new sensors design, e.g. for

- Implants and catheters for intravascular, intracardiac or neurovascular blood pressure or force feedback

- Pressure in other body organs: implants for intraocular pressure (IOP), intracranial pressure, bladder pressure, stomach pressure

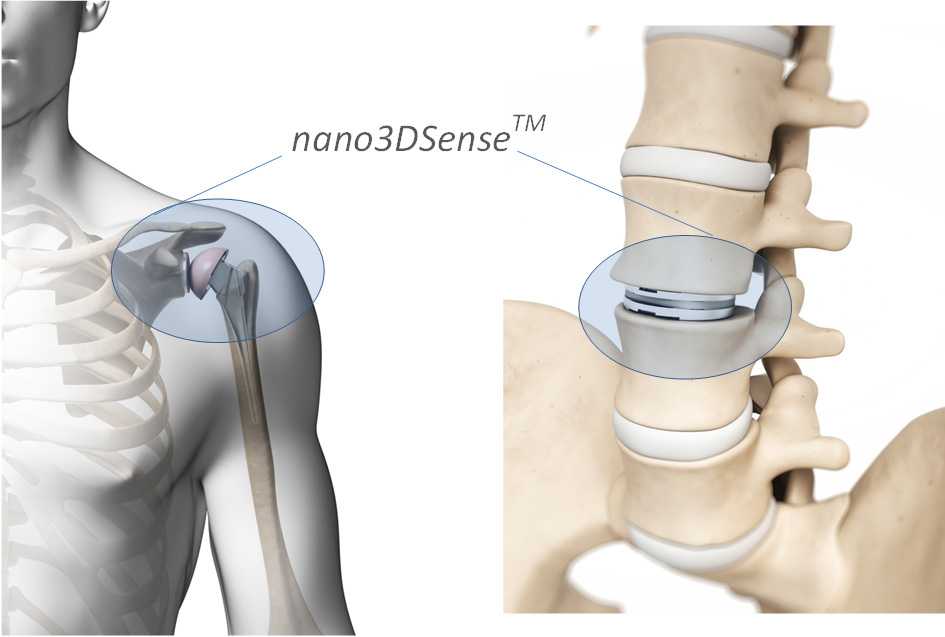

- True 3D force sensors directly adaptable on biocompatible implants, cathters and other medical devices

- Implants for blood sugar sensors for continuous glucose monitoring (CGM)

- Minimally invasive dimensions of the transducer (e.g. pressure diaphragm), down to a diameter of < 100 µm

- Advantageous use of versatile transducer materials, such as biocompatible steel, polymers or ceramics, e.g. for long-term implantable pressure sensors or catheters

- Thanks to the flexible 3D printing method, medical devices can be easily equipped with high-performance sensor functionality even under difficult boundry conditions, e.g. for highly sophisticated 3D force sensors on complicated transducers

- Best linearity behavior, low power consumption and long-term stability for high-precision measurements

Do you develop or produce medical catheters, implants or equipment and would like to learn more about nano3DSense?

Please contact us: We provide customized advice regarding the application possibilities of nano3DSense for your specific medical applications.

You can also request a demo and thoroughly test nano3DSense.

Read More:

What We Can Do for You

Tailored Customer Solutions in Medicine

Medical Sensors for Implants and Catheters

⇒Point of Care (POC) Diagnostics

Sensors for MEMS/NEMS

Ultra-Small Force Sensors

Rapid Prototyping