How to Achieve Ultrafast and Compact Atomic Force Microscopy?

(courtesy: FP7-Project ALBICAN / FALCON)

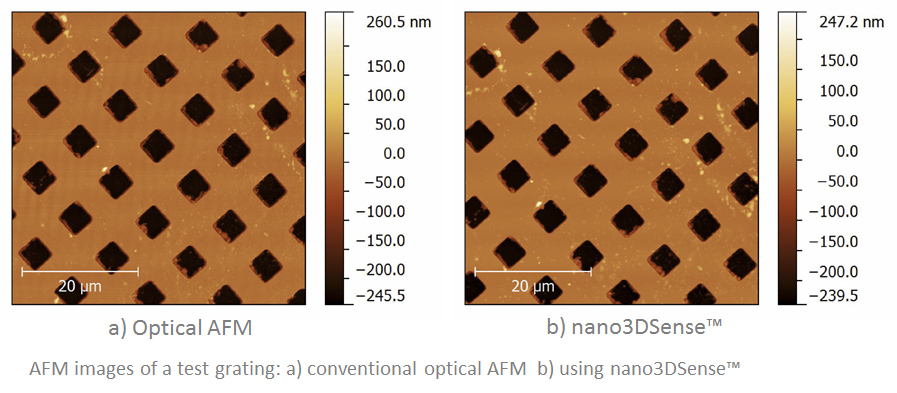

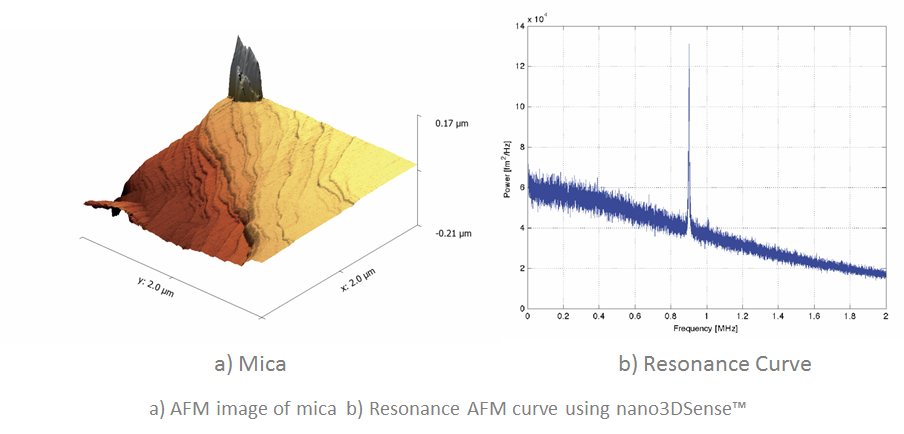

The imaging speed of atomic force microscopy (AFM) normally increases with the resonance frequency of the cantilever. The resonance frequency can be purposefully influenced e.g. with smaller cantilever and the selection of suitable materials. Furthermore, the overall signal-to-noise ratio and image quality are significantly improved.

Using self-sensing cantilevers with nano3DSense, another speed improvement can be achieved, which is immediately noticeable in the performance: With the integration of the sensing unit on the cantilever, no complicated laser optics is required anymore to operate the AFM. Instead of having to move the inert sample stage, the more dynamic measuring head must be traveled across the sample only. This fundamentally simplifies the AFM architecture, which can be newly arranged in a space-saving manner. In addition to the reduced equipment size, the annoying calibration effort of optical AFMs is omitted as well.

In the cases, where traditional methods such as piezoresistors or laser optics fail, self-sensing cantilevers for AFM, based on nano3DSense technology, are the safe alternative: whether advantageously during space-saving AFM integration into microscopic instruments, such as scanning electronic microscopes (SEM), for power-consuming analyses of biological samples with video rates in R&D, in high-resolution force microscopy, e.g. on cells or molecules, or for fast wafer and mask inspection in semiconductor industry.

Pioneering Work for Industry and Research Using Self-Sensing Cantilevers with nano3DSense

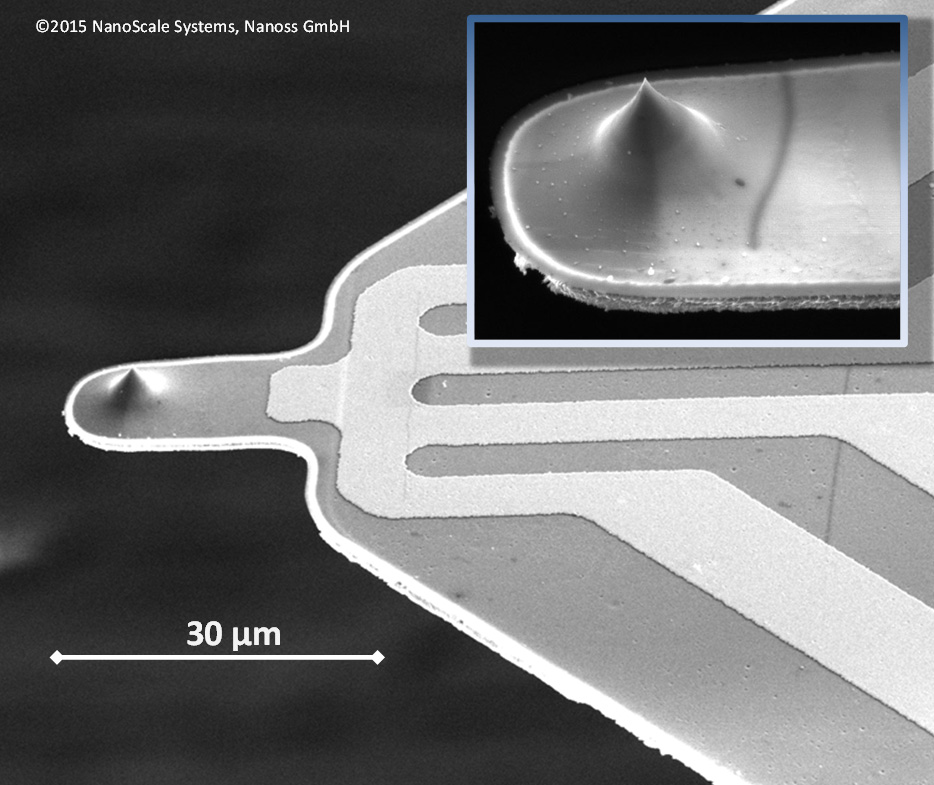

nano3DSense provides powerful and dedicated force sensing capabilities, even under difficult conditions on cantilever and measuring environment. If needed, ultra-compact AFM cantilevers with unrivaled small dimensions of less than 1 micron (µm) can be equipped with integrated force sensors as full bridge.

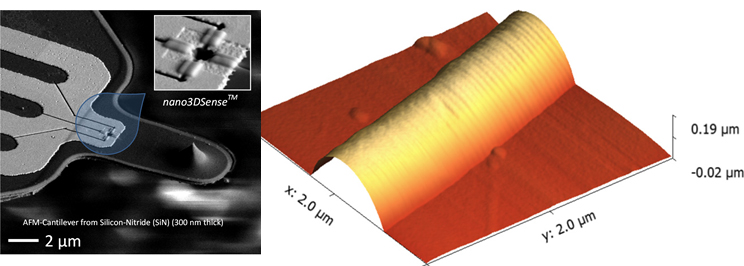

Compared to conventional piezoresistive AFM cantilever, the new self-sensing cantilever for AFM with nano3DSense have a great benefit in material freedom: In this context, the cantilever material does not matter anymore and can be chosen flexibly according to the real requirements. In addition to silicon (Si), SiN, SU8, steel, and many other materials are available to flexibly find the proper customized solution for every application purpose in industry and research. Using nano3DSense, the cantilever, core of every AFM, perfectly adapts to the measuring environment – and not the other way around!

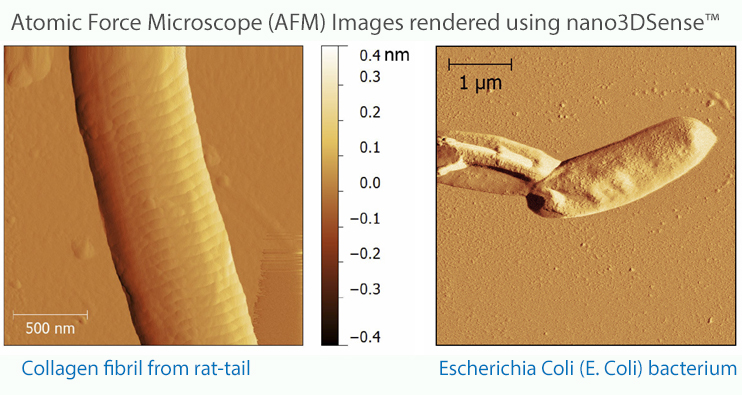

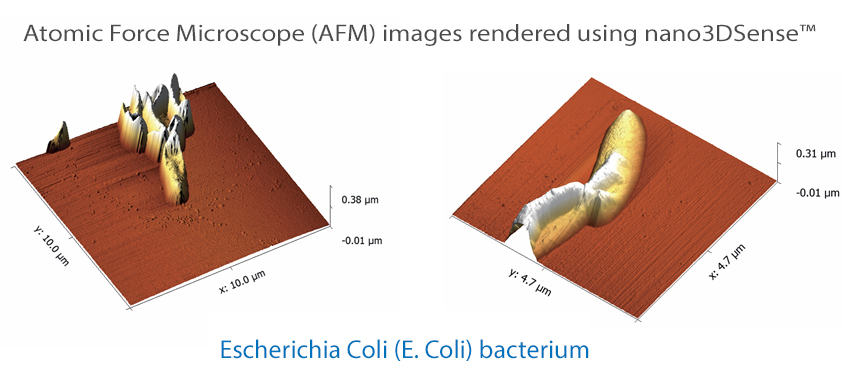

Figure: Left side: Self-sensing AFM cantilever with integrated nano3DSense force sensor as full bridge. Right side: AFM image of a collagen fiber from the tail of a rat (courtesy: FP7-Project ALBICAN / FALCON)

Convince yourself of the many advantages of the new AFM platform that gives you the ultimate flexibility for your AFM probes.

The Benefit of Optical and Laser free Instruments

Using the self-sensing cantilevers for atomic force microscopy (AFM), we e.g. replace the tricky laser-optical components of AFM with a small sensing unit, which is practically integrated on the cantilever. This decisively simplifies the architecture of AFM and other instruments with laser optics, as compacter devices are possible and there is no need for laser calibration anymore.

The integration of AFM into instruments such as scanning electron microscopes (SEM) or optical microscopes is significantly simplified with the optics-free architecture. Furthermore, many additional AFM applications, e.g. in cell analytics and force spectroscopy, can be advantageously realized without laser optics.

Nanoss GmbH has pioneered in this field to offer optimum solutions even under extreme requirements on the sample environment.

Advantages at a Glance

Convince yourself of the performance and versatile application fields of the nano3DSense platform for your own AFM ideas:

- Self-sensing cantilever for compact and fast atomic force microscopy without the need for laser calibration

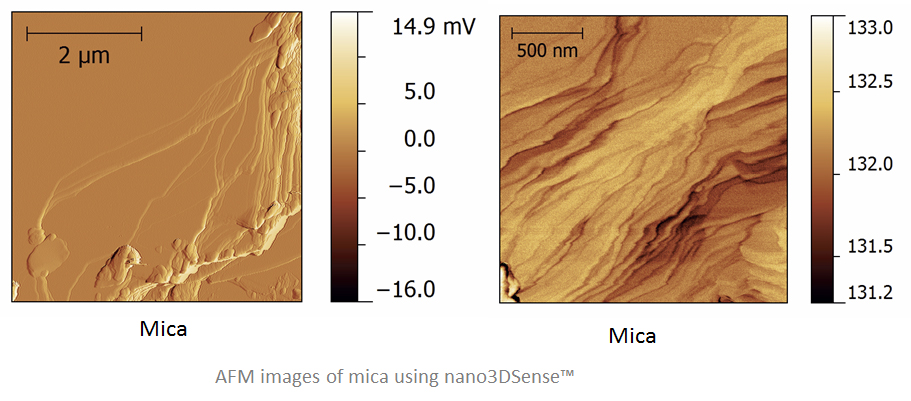

- Excellent performance characteristics with respect to linearity behavior and long-term stability for high-precision AFM imaging

- Free selection of cantilever material, e.g. silicon, silicon nitride, SU8, etc., for flexible application possibilities in different measuring environments (“soft” or “hard”), such as biological samples in fluids or ultra-high vacuum (UHV)

- High achievable resonance frequencies through the use of suitable materials and cantilever with ultra-compact dimensions down to < 1 µm

- Many further unique advantages, e.g. real 3D force sensor with significantly simplified design without laser optics

We closely collaborate with AFM developers and manufacturers to meet new challenges.

Please contact us: Discover the various application possibilities of the nano3DSense technology for your own ideas.

You can also request a demo and thoroughly test nano3DSense.

Read More:

What We Can Do for You

Tailored Customer Solutions in Medicine

Medical Sensors for Implants and Catheters

Point of Care (POC) Diagnostics

Sensors for MEMS/NEMS

Ultra-Small Force Sensors

⇒Rapid Prototyping